Views: 29 Author: Site Editor Publish Time: 2023-05-07 Origin: Site

Roofing coil nails are essential for any roofing project, providing the secure connection between roofing materials and the underlying structure. This article will explore the best practices for using roofing coil nails, ensuring that your work is efficient, safe, and long-lasting. From choosing the right type of nail to maintaining your equipment, we'll cover everything you need to know.

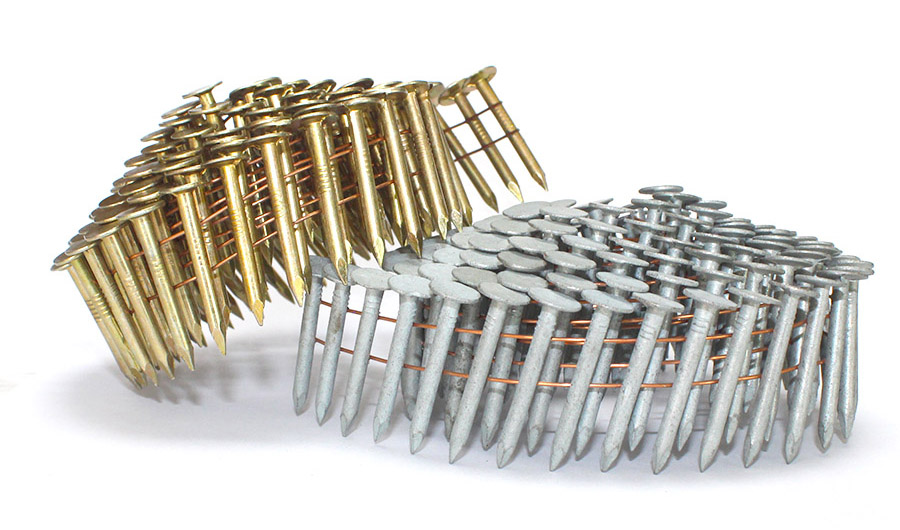

Coil nails are a popular choice in the roofing industry due to their versatility, efficiency, and ease of use. They allow for quick and consistent nailing, making it easier for roofers to complete projects on time. Additionally, coil nails are known for their durability and holding power, ensuring the roof can withstand various weather conditions.

There are several types of roofing coil nails, each with its unique advantages:

These nails are coated with a layer of zinc, providing protection against rust and corrosion. They are suitable for most roofing applications, especially in areas with moderate humidity.

Stainless steel nails are highly resistant to rust and corrosion, making them ideal for coastal regions or areas with high humidity.

Lightweight and corrosion-resistant, aluminum nails are a good choice for certain roofing materials, such as aluminum or metal roofs.

When selecting coil nails for your roofing project, consider the following factors:

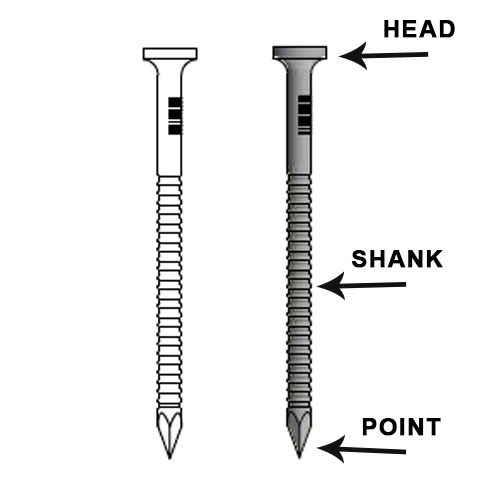

Choose a nail length that will provide a secure connection without penetrating the roof deck.

A thicker diameter provides increased holding power but may require more force during installation.

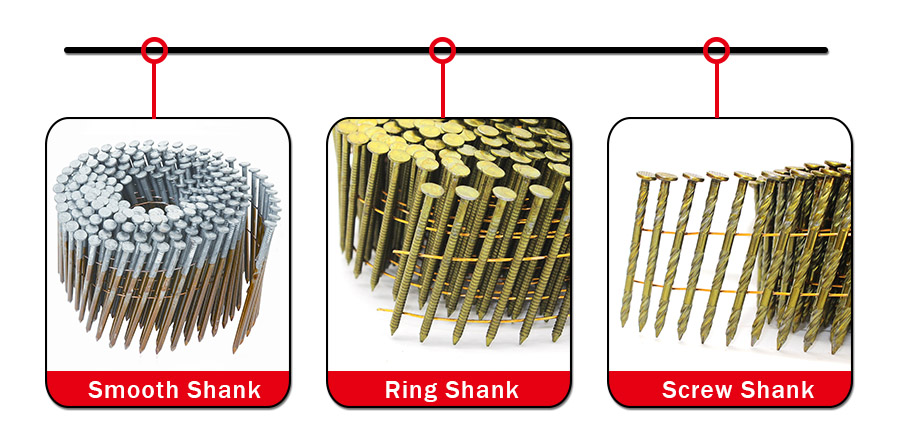

Different shank types offer varying levels of grip and holding power. Options include smooth, ring, and screw shanks.

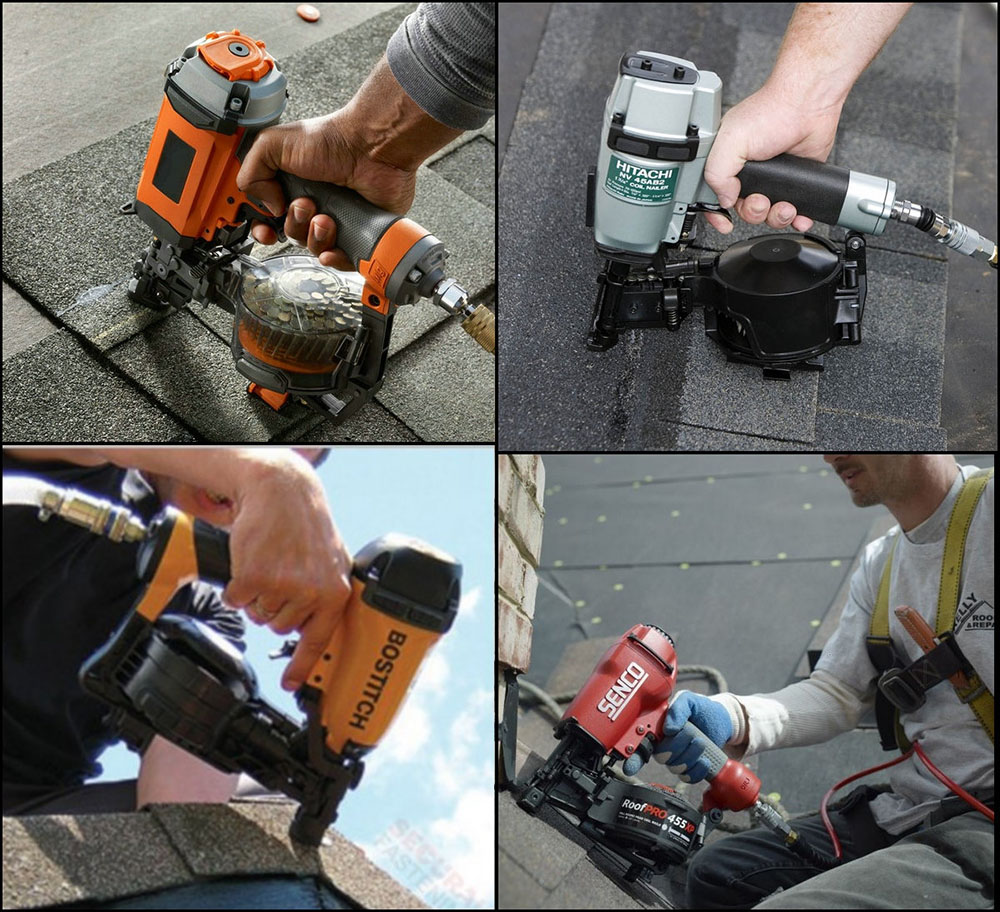

Selecting the right coil nail gun is crucial for efficient and accurate nailing. Look for features such as adjustable depth control, easy loading, and a comfortable grip. Additionally, consider the nail gun's compatibility with the coil nails you've chosen.

CRN45 ROOFING COIL NAILER

CRN45A ROOFING COIL NAILER

To ensure the best results, follow these best practices when using roofing coil nails:

Load the nail gun according to the manufacturer's instructions, ensuring the nails are oriented correctly and the coil is securely in place.

Adjust the air pressure to the recommended level for the specific nail gun and nails you're using.

Set the depth control to drive the nails to the appropriate depth, ensuring they are flush with the roofing material without overdriving or underdriving them.

Always prioritize safety when working with roofing coil nails by following these guidelines:

Wear safety glasses or goggles to protect your eyes from debris and potential nail ricochets.

Use gloves to protect your hands from cuts, scrapes, and punctures while handling roofing materials and nails.

When working on a roof, utilize appropriate fall protection equipment, such as harnesses and safety nets, to prevent injuries from falls.

To keep your coil nail gun in optimal condition, perform regular maintenance:

Clean your nail gun regularly, removing dirt and debris from the magazine, nose, and trigger area.

Lubricate moving parts with a few drops of pneumatic tool oil daily to prevent friction and wear.

Check your nail gun for signs of wear or damage, such as cracks, loose fasteners, or worn seals, and replace or repair as needed.

If you encounter issues with your coil nail gun, consider these common problems and their solutions:

Clear any jams by disconnecting the air supply, releasing the magazine, and removing the obstructing nails or debris.

If you notice air leaks, check for damaged seals, loose connections, or cracked components, and replace or repair as needed.

Misfires may result from low air pressure, a worn trigger valve, or damaged seals. Adjust the air pressure or replace any damaged components.

Using roofing coil nails effectively and safely is crucial for a successful roofing project. By understanding the different types of coil nails, selecting the appropriate nail gun, following best practices, and maintaining your equipment, you can ensure a secure and lasting roof installation. Stay safe, and happy roofing!